Ideal Practices for Preventing Weld Undercut: Understanding the Essentials

Ideal Practices for Preventing Weld Undercut: Understanding the Essentials

Blog Article

Understanding the Causes and Solutions for Undercut Welding in Metal Construction Processes

In the realm of metal construction processes, the occurrence of undercut welding positions a considerable difficulty that demands a comprehensive understanding of its causes and viable solutions. The intricate interaction of numerous variables throughout welding operations can result in this undesirable phenomenon, impacting the architectural honesty and general high quality of the welded joints - Preventing weld undercut. By dissecting the source of undercut welding and checking out effective remedial measures, makers can raise the requirement of their workmanship and make certain the manufacturing of perfect metal parts

Typical Root Causes Of Undercut Welding

Frequently neglected in steel manufacture, undercut welding takes place due to numerous factors that demand precise interest and expertise to be successfully alleviated. In addition, inappropriate welding strategies, such as making use of the incorrect welding angle or take a trip rate, can additionally add to damage development. The selection of welding criteria, such as voltage, existing, and cable feed rate, plays a considerable function in the incident of undercut welding.

Effect of Incorrect Welding Parameters

Inaccurate welding specifications can dramatically compromise the stability and high quality of bonded joints in metal fabrication processes. The effect of wrong welding criteria manifests in different means, leading to architectural weaknesses and problems in the welded elements. Careful focus to welding criteria is paramount to guarantee the manufacturing of premium welds with the wanted mechanical properties and structural integrity.

Effect of Improper Torch Angle

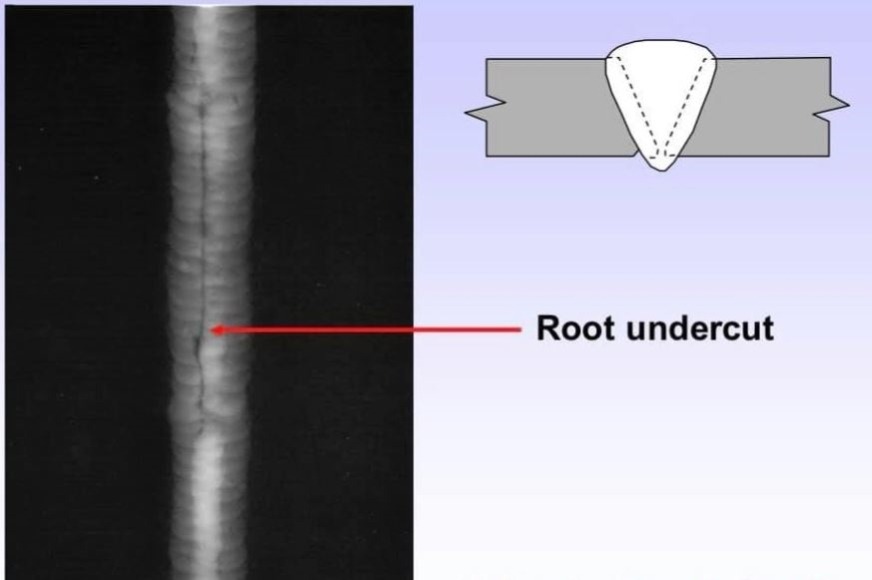

Inappropriate lantern angle in welding procedures can substantially affect the quality and integrity of the last weld joints in steel construction processes. Undercutting is a common welding issue where a groove creates along the weld toe, deteriorating the joint and jeopardizing its structural honesty.

A lantern angle that is as well steep can result in inadequate penetration, insufficient combination, and enhanced spatter. On the various other hand, a lantern angle that is as well shallow can cause extreme penetration, burn-through, and distortion of the base product. Preventing weld undercut. Correct torch angle is important for ensuring regular weld high quality, strength, and look

To avoid undercutting and various other flaws brought on by inappropriate lantern angles, welders should be educated to preserve the correct lantern angle throughout the welding process. Routine monitoring and change of torch angles throughout welding can help attain sound welds with marginal problems.

Duty of Inadequate Welding Methods

One more element of insufficient welding techniques is improper weld preparation. Inadequate cleansing of find out here the base steels, inaccurate joint style, or inadequate edge preparation can all add to damage welding. In addition, poor securing gas protection or utilizing the wrong kind of gas can cause insufficient combination and the formation of undercut defects.

To deal with the role of poor welding methods in metal construction procedures, it is vital to provide extensive training for welders. Proper education and learning on welding criteria, joint preparation, and shielding gas option can assist stop undercut welding and ensure top notch welds in metal fabrication projects.

Reliable Solutions for Undercut Welding

Attending to undercut welding in steel manufacture requires implementing effective solutions to enhance weld quality and structural stability. One of the key solutions to deal with undercut is to change welding specifications such as voltage, existing, and take a trip speed to ensure appropriate warm input and fusion. By fine-tuning these settings, welders can protect against excessive melting of the base steel and filler product, minimizing the chance of undercut formation.

Furthermore, appropriate joint prep work is critical in protecting against undercut. Making sure tidy base metal surfaces cost-free of impurities and making use of the suitable bevel angle can help advertise far Home Page better weld infiltration and decrease the danger of undercut - Preventing weld undercut. Using appropriate welding methods, such as weaving or oscillating the torch, can likewise aid in distributing heat uniformly and loading the weld joint appropriately, reducing the opportunity of undercut flaws

Moreover, selecting the right welding consumables, consisting of electrodes and filler steels, is vital in alleviating undercut. Using products with ideal chemical make-ups and mechanical properties can add to attaining audio welds with very little undercut. Regular evaluation and quality assurance actions ought to likewise be carried out to find and deal with undercut issues without delay, ensuring the general stability of made steel components.

Conclusion

Finally, comprehending the reasons and options for undercut welding in metal construction processes is essential for attaining top notch welds. By resolving typical causes such as inaccurate welding specifications, improper torch angle, and poor welding strategies, welders can stop undercutting and ensure solid, long lasting welds. It is vital to take note of these elements and implement reliable services to improve the total welding process and last product quality.

Report this page